Пакупнікі шукаюць лепшаешчэкавая драбнілкаУ 2025 годзе часта выбіраюць Metso Outotec Nordberg серыі C. Гэтая мадэль вылучаецца сваёй высокай прадукцыйнасцю, надзейнасцюдэталі драбнілкі, і лёгкае абслугоўванне. Такія вядучыя канкурэнты, як Sandvik, Terex і Kleemann, таксама лідзіруюць на рынку. Большасць пакупнікоў шукаюцьвысокамарганцавая сталь, трывалыдэталі шчэкавай драбнілкіі падтрымка як сківіцы, так ігіраторная драбнілкапатрэбы.

Многія пакупнікі арыентуюцца на гэтыя ключавыя крытэрыі:

- Рэпутацыя і падтрымка вытворцы

- Доўгатэрміновыя эксплуатацыйныя выдаткі

- Перадавыя тэхналогіі і функцыі бяспекі

| Кампанія | Роля на рынку шчокавых драбнілак у 2025 годзе | Асноўныя моманты |

|---|---|---|

| Metso Outotec | Уваходзіць у лік вядучых кампаній з доляй рынку 30-35% | Сусветны лідар; моцныя інавацыі і пашырэнне |

| Sandvik AB | Найбуйнейшая кампанія па долі рынку | Вядомы сваімі энергаэфектыўнымі аўтаматызаванымі драбільнымі ўстаноўкамі |

| Карпарацыя Terex | Асноўны гулец | Трывалыя, няпатрабавальныя да абслугоўвання драбільныя машыны |

| Клеман | Актыўны ў Паўночнай Амерыцы | Акцэнт на шчэкавых драбільнах на гусенічным ходу |

Асноўныя высновы

- Выбірайце шчэкавыя драбнілкі з высокай прадукцыйнасцю,лёгкае абслугоўванне, і надзейная падтрымка, каб зэканоміць грошы і час у доўгатэрміновай перспектыве.

- Шукайце машыны, якія добра спраўляюцца з вашым тыпам матэрыялу і прапануюць высокую магутнасць драбнення, каб павысіць прадукцыйнасць вашых праектаў.

- Улічвайце агульныя выдаткі на валоданне, у тым ліку спажыванне энергіі і абслугоўванне, а не толькі цану пакупкі, каб знайсці найлепшае суадносіны кошту і якасці.

Прадукцыйнасць і прадукцыйнасць шчэкавай драбнілкі

Драбнільная магутнасць

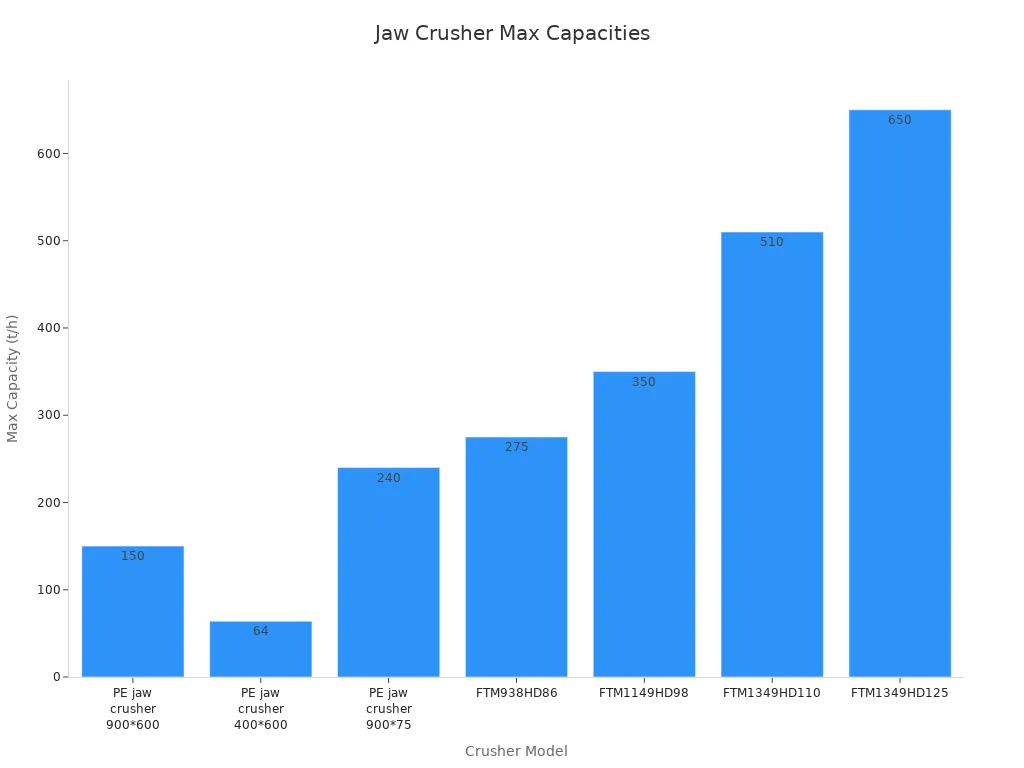

Магутнасць драбнення паказвае пакупнікам, колькі матэрыялу шчэкавая драбнілка можа апрацаваць кожную гадзіну. Гэтая лічба мае вялікае значэнне для буйных праектаў. Некаторыя машыны могуць апрацаваць сотні тон усяго за адну гадзіну. Напрыклад, шчэкавая драбнілка PE 900600 можа здрабняць да 150 тон у гадзіну, у той час як шчэкавая драбнілка з ПЭ 90075 можа дасягнуць 240 тон у гадзіну. Мабільныя мадэлі, такія як FTM1349HD125, могуць апрацоўваць да 650 тон у гадзіну. Гэтыя лічбы паказваюць, чамушчэкавыя драбнілкі папулярныядля першаснага драбнення.

| Мадэль | Прадукцыйнасць (т/г) | Памер порцыі (мм) | Патрабуемая магутнасць (кВт) |

|---|---|---|---|

| ПЭ шчэкавая драбнілка 900*600 | 150 | ~500 | 75 |

| ПЭ шчэкавая драбнілка 400*600 | 16 – 64 | ~340 | 30 |

| ПЭ шчэкавая драбнілка 900*75 | 80 – 240 | ~500 | 55 |

| Мадэль мабільнай шчэкавай драбнілкі | Прадукцыйнасць (т/г) | Максімальны памер падачы (мм) |

|---|---|---|

| FTM938HD86 | 85 – 275 | 500 |

| FTM1149HD98 | 110 – 350 | 550 |

| FTM1349HD110 | 215 – 510 | 660 |

| FTM1349HD125 | 280 – 650 | 800 |

Шчэкавыя драбнілкі звычайна маюць большую гадзінную прадукцыйнасць, чым конусныя. Шчэкавыя драбнілкі сярэдняга памеру часта перапрацоўваюць ад 300 да 600 тон у гадзіну, у той час як падобныя конусныя драбнілкі ў сярэднім перапрацоўваюць ад 200 да 500 тон у гадзіну. Гэта робіць шчэкавыя драбнілкі найлепшым выбарам для першаснага драбнення.

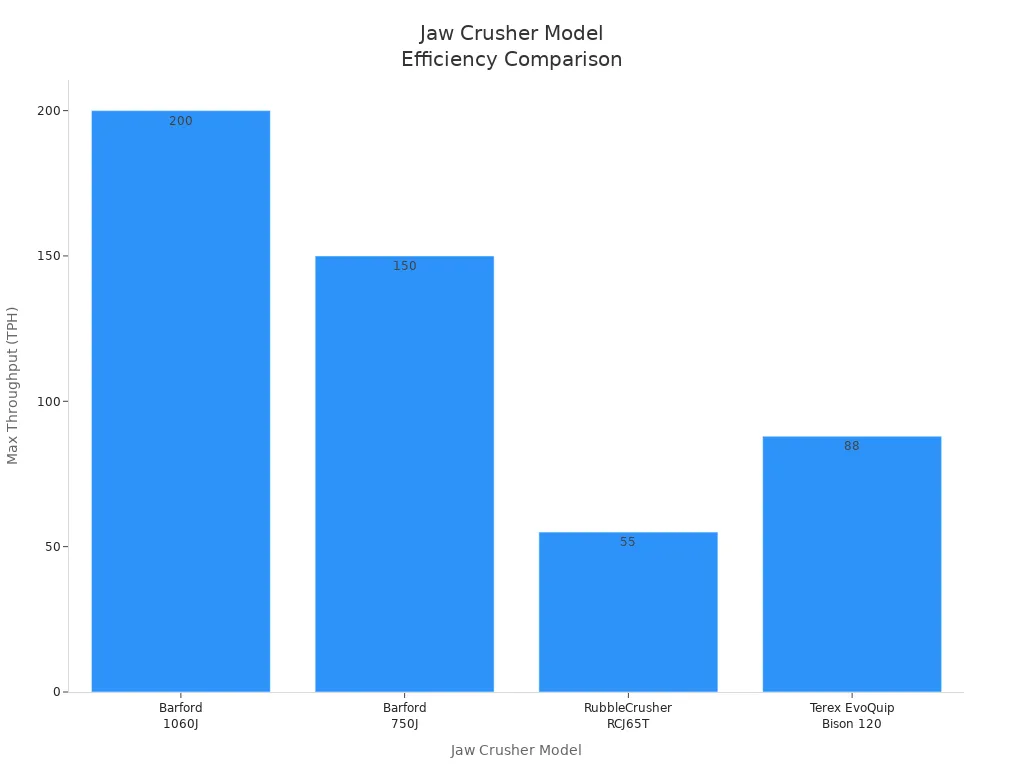

Эфектыўнасць і якасць прадукцыі

Эфектыўнасць азначае, наколькі добра шчэкавая драбнілка ператварае вялікія камяні ў меншыя, прыдатныя для выкарыстання кавалкі. Якасць прадукцыі залежыць ад памеру і формы здробненага матэрыялу. Прапускная здольнасць, якая вымяраецца ў тонах у гадзіну (ТПГ), з'яўляецца асноўным спосабам параўнання эфектыўнасці. Большыя шчэкавыя скрыні азначаюць больш высокую прапускную здольнасць. Напрыклад, Barford 1060J можа перапрацоўваць да 200 ТПГ, а Terex EvoQuip Bison 120 — да 88 ТПГ. Цвёрдасць матэрыялу, налады драбнілкі і навыкі аператара ўплываюць на гэтыя лічбы.

| Мадэль шчаковай драбнілкі | Прапускная здольнасць (TPH) | Кошт (USD) |

|---|---|---|

| Барфард 1060J | 60 – 200 | 420 000 долараў ЗША |

| Барфард 750J | 30 – 150 | 329 500 долараў ЗША |

| Драбнілка RCJ65T | 6 – 55 | 160 000 долараў ЗША |

| Terex EvoQuip Bison 120 | Да 88 | 228 000 долараў ЗША |

Больш цвёрдыя матэрыялы, такія як граніт, запавольваюць прапускную здольнасць у параўнанні з больш мяккімі матэрыяламі, такімі як бетон. Тэхнічнае абслугоўванне і ўмовы навакольнага асяроддзя таксама ўплываюць на эфектыўнасць шчэкавай драбнілкі.

Адаптыўнасць да матэрыялаў

Шчэкавая драбільная машына павінна працаваць з рознымі тыпамі матэрыялаў. У некаторых праектах выкарыстоўваюцца цвёрдыя пароды, а ў іншых — перапрацаваны бетон або руды. Шчэкавыя драбільныя машыны прызначаны для выканання складаных задач. Яны разбіваюць вялікія, цвёрдыя матэрыялы на больш дробныя кавалкі для далейшай апрацоўкі. Гэта робіць іх карыснымі ў горназдабыўной прамысловасці, будаўніцтве і перапрацоўцы адходаў.

- Шчэкавыя драбнілкі добра працуюць для першаснай перапрацоўкі руды, што робіць іх важнымі ў горназдабыўной прамысловасці.

- Яны дапамагаюць вырабляць будаўнічыя запаўняльнікі шляхам драбнення горных парод і камянёў.

- У многіх праектах па перапрацоўцы адходаў выкарыстоўваюцца шчэкавыя драбнілкі для апрацоўкі бетону і іншых адходаў.

- Сучасныя машыны маюць элементы кіравання, якія дазваляюць аператарам рэгуляваць памер выходнага матэрыялу, што дапамагае пры працы з рознымі матэрыяламі.

- Іх канструкцыя дазваляе ім апрацоўваць матэрыялы рознай цвёрдасці, ад граніту да мякчэйшага бетону.

Двухрычажныя шчэкавыя драбнілкі выдатна падыходзяць для цвёрдых і абразіўных парод. Аднарычажныя мадэлі хутчэйшыя і больш кампактныя, але яны хутчэй зношваюцца. Абодва тыпы з часам удасканальваліся для апрацоўкі большых памераў сыравіны і больш цвёрдых матэрыялаў.

Шчэкавыя драбнілкі менш зношваюцца, чым ударныя, пры працы з цвёрдымі матэрыяламі. Іх трывалая канструкцыя і гнуткая канструкцыя робяць іх разумным выбарам для многіх галін прамысловасці.

Кошт і поўны аб'ём валодання шчэкавай драбнілкай

Пачатковая цана пакупкі

Першае, на што звяртаюць увагу большасць пакупнікоў, — гэта цана. Некаторыя шчэкавыя драбнілкі каштуюць танней, а іншыя — даражэй, але прапануюць больш функцый. Напрыклад, базавая мадэль можа каштаваць ад 100 000 долараў. Пашыраныя мадэлі адвядучыя брэндыКошт такіх кампаній, як Metso Outotec, Sandvik або Terex, можа дасягаць 500 000 долараў і больш. Кошт залежыць ад памеру, магутнасці і тэхналогіі. Пакупнікам таксама варта ўлічваць дадатковыя выдаткі, такія як дастаўка, устаноўка і налада. Часам больш высокая пачатковая цана азначае лепшую якасць зборкі або дадатковыя функцыі бяспекі.

Парада: Заўсёды пытайцеся, што ўваходзіць у цану. Некаторыя брэнды прапануюць бясплатнае навучанне або запасныя часткі пры куплі.

Эксплуатацыйныя выдаткі

Валоданне шчэкавай драбільнай машынай азначае больш, чым проста аплату абсталявання. Штодзённыя выдаткі могуць хутка назапашвацца. Да іх адносяцца энергія, праца, тэхнічнае абслугоўванне і расходныя матэрыялы. Энергія часта складае найбольшую долю, асабліва на буйных заводах. Высокаэфектыўныя рухавікі і разумнае кіраванне могуць дапамагчы знізіць рахункі за электрычнасць. Выдаткі на працу залежаць ад колькасці неабходных аператараў і тэхнікаў. Кваліфікаваныя работнікі могуць зарабляць больш, але яны могуць падтрымліваць машыну ў бесперабойнай працы.

Вось табліца, якая паказвае тыповыя эксплуатацыйныя выдаткі:

| Катэгорыя выдаткаў | Падрабязнасці і тыповыя дыяпазоны выдаткаў |

|---|---|

| Выдаткі на працу | Аператары: 30 000–100 000 долараў ЗША штогод; тэхнікі па тэхнічным абслугоўванні: 50 000–200 000 долараў ЗША штогод; залежыць ад рэгіёна і кваліфікацыі. |

| Выдаткі на энергію | Спажыванне электраэнергіі значнае; заводам можа спатрэбіцца некалькі мегават; выдаткі могуць дасягаць дзясяткаў тысяч штогод. |

| Тэхнічнае абслугоўванне і запасныя часткі | Выдаткі на тэхнічнае абслугоўванне складаюць 5-15% ад пачатковага кошту абсталявання штогод; уключаюць зношвальныя дэталі, такія як футроўкі, рамяні, сіта; змазку і вадкасці таксама ўключаны. |

| Расходныя матэрыялы | Змазкі і вадкасці, неабходныя для працы драбільнай машыны; кошт залежыць ад умоў эксплуатацыі. |

| Транспарт і лагістыка | Выдаткі залежаць ад адлегласці да сыравіны і рынкаў; уключаюць грузаперавозкі, перавезці груз і выдаткі на дастаўку. |

Энергетыка можа складаць палову агульных эксплуатацыйных выдаткаў. Выкарыстанне высокаэфектыўных рухавікоў або прывадаў са зменнай частатой (ЧРП) можа скараціць спажыванне энергіі да 30%. Рэгулярнае тэхнічнае абслугоўванне дапамагае пазбегнуць дарагіх паломак. Планавая замена сківіц і ўкладышаў дазваляе падоўжыць працу машыны. Выбар правільных змазачных матэрыялаў і вадкасцей таксама дазваляе зэканоміць грошы з цягам часу.

Доўгатэрміновая каштоўнасць

Сапраўдная каштоўнасць шчэкавай драбнілкі выяўляецца з гадамі выкарыстання. Некаторыя машыны спачатку каштуюць даражэй, але пазней дазваляюць зэканоміць грошы. Трывалыя дэталі, лёгкае абслугоўванне і добрая падтрымка з боку вытворцы — усё гэта мае значэнне. Машыны з трывалымі рамамі івысакаякасная стальслужаць даўжэй і патрабуюць радзей рамонту. Брэнды, якія прапануюць планавыя праграмы тэхнічнага абслугоўвання, дапамагаюць скараціць час прастою і падтрымліваць стабільныя выдаткі.

Заўвага: Тэхнічнае абслугоўванне звычайна каштуе 5-15% ад пачатковай цаны штогод. Прафілактычны догляд і рэгулярныя праверкі могуць знізіць гэтыя выдаткі і падтрымліваць працаздольнасць драбільнай устаноўкі.

Шчэкавая драбнілка, якая спажывае менш энергіі і патрабуе радзей рамонту, будзе каштаваць менш у доўгатэрміновай перспектыве. Пакупнікам варта ўлічваць агульны кошт валодання, а не толькі цэннік. Добрая падтрымка, лёгкі доступ да запасных частак і высокая кошт перапродажу — усё гэта спрыяе лепшай доўгатэрміновай эканоміі.

Прыдатнасць да ўжывання шчэкавай драбнілкі

Універсальнасць у розных галінах прамысловасці

Шчэкавая драбільная машына працуе ў многіх галінах прамысловасці. Кампаніі выкарыстоўваюць яе ў горназдабыўной прамысловасці, будаўніцтве, перапрацоўцы адходаў, зносе і здабычы кар'ераў. Яны здрабняюць цвёрдыя пароды, бетон з арматурай і нават перапрацаваны асфальт. Некаторыя мадэлі, такія як Lippmann, спраўляюцца як з вялікімі, так і з малымі работамі. Гэтыя машыны могуць апрацоўваць граніт, вапняк і іншыя цвёрдыя матэрыялы. Мабільныя шчэкавыя драбільныя машыны дапамагаюць брыгадам працаваць на месцы, нават у аддаленых месцах. Такія функцыі, як падаўленне пылу і магнітныя сепаратары, робяць іх больш бяспечнымі і эфектыўнымі.

- Горназдабыўныя кампаніі выкарыстоўваюць шчэкавыя драбнілкі для драбнення руды.

- Будаўнічыя брыгады драбняць скалы для будаўніцтва дарог і мастоў.

- Перапрацоўчыя заводы ператвараюць стары бетон і асфальт у новыя матэрыялы.

- Брыгады па зносе выкарыстоўваюць іх для хуткай апрацоўкі смецця.

- Аператары кар'ераў разлічваюць на іх для забеспячэння стабільнай здабычы.

Шчэкавыя драбнілкі прапануюць нізкія эксплуатацыйныя выдаткі і простую канструкцыю. Іх здольнасць апрацоўваць мноства матэрыялаў робіць іх выдатным выбарам для розных праектаў.

Варыянты налады і мадэлі

Вытворцы ведаюць, што кожная праца адрозніваецца ад іншых. Яны прапануюць мноства спосабаў налады шчэкавай драбнілкі. Пакупнікі могуць выбіраць паміж тыпамі з падвойным і аднарычажным пераключэннем. Мадэлі з падвойным пераключэннем добра падыходзяць для складаных работ і вялікіх памераў загрузкі. Драбнілкі з адным пераключэннем прасцей у абслугоўванні і каштуюць танней.

У табліцы ніжэй паказаны некаторыя распаўсюджаныя параметры налады:

| Аспект налады | Опцыі і функцыі |

|---|---|

| Мабільнасць | Партатыўны для перамяшчэння паміж пляцоўкамі, стацыянарны для фіксаваных месцаў |

| Крыніца харчавання | Дызельныя рухавікі для аддаленых раёнаў, электрарухавікі для эканоміі энергіі |

| Зношваюцца дэталі | Сучасныя сплавы і гібрыдныя матэрыялы для больш працяглага тэрміну службы |

| Тэхналогіі | Лічбавы маніторынг, аўтаматызацыя, модульныя канструкцыі для хуткага абслугоўвання |

| Рэгіянальны фокус | Кантроль выкідаў, высокая ёмістасць або лічбавыя функцыі ў залежнасці ад мясцовых патрэб |

Такія брэнды, як Metso Outotec, Sandvik, Terex і Kleemann з'яўляюцца лідарамі ў прадастаўленні такога выбару. Яны забяспечваюць моцную падтрымку і запчасткі, якія адпавядаюць патрэбам кожнага кліента.

Тэхнічнае абслугоўванне і прастой шчокавай драбнілкі

Прастата абслугоўвання

Многія аператары жадаюць мець шчэкавую драбнілку, якую лёгка абслугоўваць. Вядучыя брэнды распрацоўваюць свае машыны з платформамі для абслугоўвання і шырокімі кропкамі доступу. Гэтыя функцыі дапамагаюць работнікам хутка і бяспечна дабірацца да ключавых дэталяў. Вось некалькі спосабаў, як лепшыя машыны спрашчаюць абслугоўванне:

- Платформы абслугоўвання забяспечваюць бяспечны і хуткі доступ да рухавіка, рамянёў і сківіц.

- Некаторыя машыны маюць універсальныя змазачныя блокі. Гэтыя блокі дазваляюць лёгка штодзённа змазваць шлангі, падшыпнікі і паверхні слізгання.

- Сістэмы астуджэння, такія як радыятары і алейныя радыятары, патрабуюць рэгулярнай чысткі. Лёгкі доступ дапамагае падтрымліваць гэтыя дэталі ў належнай працы.

- Графік прафілактычнага тэхнічнага абслугоўвання і кваліфікаваныя тэхнікі дапамагаюць скараціць час прастою.

Аператары таксама правяраюцьзношваюцца дэталі, напрыклад, плашкі для сківіц, часта. Своечасовая замена гэтых дэталяў дазваляе падтрымліваць працу машыны і прадухіляць раптоўныя прыпынкі.

Даўгавечнасць і зносаўстойлівасць

Даўгавечнасць мае значэнне для кожнай шчэкавай драбільнай машыны.Папулярныя брэндывыкарыстоўваюць трывалыя матэрыялы і разумную інжынерыю для барацьбы са зносам. У табліцы ніжэй паказана, як некаторыя брэнды ствараюць трывалыя машыны:

| Брэнд | Матэрыялы і характарыстыкі зношвальных дэталяў | Інавацыі ў інжынерыі і дызайне |

|---|---|---|

| Сандвік | Высокаякасныя сплавы для ўстойлівасці да ізаляцыі | Дакладная інжынерыя; удасканаленыя футроўкі для лепшага патоку матэрыялу |

| Metso Outotec | Зношвальныя дэталі якасці арыгінальнага вытворца (OEM) для кожнага тыпу драбнілкі | Даўгавечныя канструкцыі; акцэнт на бяспеку і ўстойлівасць |

| Калумбія Стыл | Xtralloy 24% марганцавая сталь для падоўжанага тэрміну службы | Тэрмаапрацаваныя дэталі са знятым напружаннем; двухсекцыйныя мантыі для больш працяглага выкарыстання |

Гэтыя асаблівасці дапамагаюць шчэкавым драбілкам служыць даўжэй і працаваць лепш, нават з цвёрдымі пародамі або цяжкай працай.

Наяўнасць запасных частак

Хуткае атрыманне запасных частак забяспечвае працаздольнасць шчэкавай драбнілкі. Большасць замежных брэндаў пастаўляюць дэталі прыкладна на працягу 30 дзён. Калі патрэбна драўляная форма, гэта можа заняць на 15 дзён больш. Айчынныя брэнды часта адпраўляюць дэталі на працягу 20 дзён. Такія кампаніі, як Sandvik, Terex і Metso Outotec, маюць глабальныя сэрвісныя цэнтры і моцныя дыстрыб'ютарскія сеткі. Гэта азначае, што аператары могуць знайсці дэталі і падтрымку практычна ў любым месцы. Kleemann засяроджваецца на разумных канструкцыях, якія дапамагаюць скараціць час прастою, у той час як іншыя інвестуюць у лічбавыя інструменты і гнуткія ланцужкі паставак. Гэтыя намаганні дапамагаюць падтрымліваць працу машын і рэалізацыю праектаў.

Пасляпродажная падтрымка шчэкавай драбнілкі

Гарантыйныя і сэрвісныя пагадненні

Надзейная гарантыя дае пакупнікам спакой. Вядучыя брэнды прапануюць пашыраныя гарантыйныя планы, якія дапамагаюць ператварыць нечаканыя рахункі за рамонт у пастаянныя выдаткі. Гэта дазваляе кампаніям лягчэй планаваць свае бюджэты. Пашыраныя гарантыі часта выкарыстоўваюць толькіарыгінальныя запчасткіі сертыфікаваны рамонт, які забяспечвае бесперабойную працу шчэкавай драбнілкі. Гэтыя планы таксама могуць павялічыць кошт перапродажу да 10%. Калі кампанія прадае сваё абсталяванне, гарантыя можа перайсці да новага ўладальніка. Гэта дадае дадатковую каштоўнасць і давер.

Пашыраныя гарантыі дапамагаюць знізіць агульны кошт валодання. Яны памяншаюць рызыку вялікіхрахункі за рамонті падтрымліваць надзейнасць абсталявання. Большасць брэндаў патрабуюць праверкі ў дылера перад продажам гарантыі, калі абсталяванне не пакрываецца базавай гарантыяй. Гэты этап дазваляе праверыць наяўнасць схаваных праблем.

Падтрымка кліентаў і навучанне

Добрая падтрымка кліентаў мае вялікае значэнне. Вядучыя вытворцы прапануюць праграмы навучання для аператараў і тэхнікаў. Напрыклад:

- AIMIX вучыць работнікаў карыстацца элементамі кіравання, выконваць правілы бяспекі і вырашаць распаўсюджаныя праблемы.

- KastRock засяроджваецца на бяспецы, паказваючы камандам, як рэагаваць на надзвычайныя сітуацыі і выкарыстоўваць сродкі абароны.

- Wirtgen Group праводзіць практычныя заняткі ў сучасных навучальных цэнтрах. Яны навучаюць аператараў, як дасягнуць найлепшых вынікаў і выконваць базавы рамонт.

Многія брэнды таксама прапануюць онлайн-курсы і гарачыя лініі падтрымкі. Гэтыя паслугі дапамагаюць камандам хутка вырашаць праблемы і падтрымліваць шчэкавую драбнілку ў найлепшым стане. Навучанне ўмацоўвае ўпэўненасць і дапамагае прадухіліць няшчасныя выпадкі.

Параўнальная табліца шчэкавых драбілак

Выбар патрэбнай шчэкавай драбнілкі можа быць складаным з-за вялікай колькасці даступных варыянтаў.стол побачдапамагае пакупнікам адразу ўбачыць адрозненні. Вось зручнае параўнанне лепшых мадэляў 2025 года:

| Мадэль/Марка | Дыяпазон прапускной здольнасці (т/г) | Памер падачы (мм) | Тэхнічныя моманты | Прастата абслугоўвання | Спажыванне энергіі (кВт·г/тона) | Гарантыя і падтрымка | Дыяпазон цэн (USD) | Заўвагі |

|---|---|---|---|---|---|---|---|---|

| Серыя Metso Nordberg C | 100 – 800+ | Да 1200 | Прагназуемы штучны інтэлект, высокая надзейнасць | Лёгкі доступ | 1,5 – 2,0 | Кругласутачна, моцна | 500 тыс. – 1 млн. долараў | Найлепшы варыянт для бесперабойнай працы, пашыраны маніторынг |

| Terex Powerscreen Premiertrak | 100 – 750 | Да 1000 | Універсальная магутнасць, хуткая налада | Просты | 1,7 – 2,1 | Добрыя рэгіянальныя цэнтры | 350 тыс. – 900 тыс. долараў | Высокая прапускная здольнасць, лёгкасць абслугоўвання |

| Сэндвік QJ341/CJ211 | 100 – 700 | Да 1000 | Аўтаматызацыя, эканомія паліва | Модульныя дэталі | 1,6 – 2,0 | Лічбавая падтрымка 24/7 | 400 тыс. – 950 тыс. долараў | Трывалы, патрабуе кваліфікаваных аператараў |

| Kleemann MC 120 PRO/100i EVO | 200 – 650 | Да 1200 | Дызель-электрычны, разумнае кіраванне | Модульны, хуткі | 1,5 – 2,0 | Лакальныя лічбавыя інструменты | 450 тыс. – 1 млн. долараў | Гнуткая шчыліна, больш цяжкі транспарт |

Парада: Пакупнікам варта звярнуць увагу не толькі на цану, але і на функцыі падтрымкі і абслугоўвання. Моцныя гарантыі і мясцовыя сэрвісныя цэнтры могуць зэканоміць шмат часу і грошай.

- Мадэлі Metso вылучаюцца сваёй бесперабойнай працай і разумным маніторынгам.

- Terex прапануе лёгкае абслугоўванне і высокую прапускную здольнасць.

- Sandvik робіць акцэнт на аўтаматызацыі і эканоміі паліва.

- Kleemann прапануе пашыраныя элементы кіравання і гнуткія налады.

У кожнага брэнда ёсць моцныя бакіНекаторыя лепш падыходзяць для буйных горназдабыўных работ, а іншыя — для меншых або мабільных праектаў. Пакупнікі могуць выкарыстоўваць гэтую табліцу, каб падабраць патрэбную машыну.

Шчэкавая драбільная машына Metso вылучаецца сярод пакупнікоў, якія жадаюць высокай прадукцыйнасці і разумных тэхналогій. Ім варта падбіраць характарыстыкі машыны ў адпаведнасці з патрэбамі свайго праекта.

- Доўгатэрміновая эканомія забяспечваецца трываласцю, простым абслугоўваннем і моцнай падтрымкай.

- Хуткая налада дапамагае з тэрмінамі, але самае галоўнае — гэта доўгатэрміновая каштоўнасць.

Разумныя пакупнікі ўлічваюць як кароткатэрміновыя выйгрышы, так і будучыя прыбыткі, перш чым зрабіць выбар.

Часта задаваныя пытанні

Што робіць Metso Nordberg серыі C найлепшым выбарам па суадносінах цаны і якасці?

ГэтыСерыя Metso Nordberg Cзабяспечвае высокую прадукцыйнасць, лёгкае абслугоўванне і надзейную падтрымку. Многія пакупнікі давяраюць гэтай мадэлі як для вялікіх, так і для малых праектаў.

Як часта аператары павінны замяняць зношвальныя дэталі шчэкавай драбнілкі?

Аператары звычайна правяраюцьзношваюцца дэталікожныя некалькі тыдняў. Яны замяняюць іх, калі бачаць расколіны, сколы або патанчэнне. Рэгулярныя праверкі дапамагаюць прадухіліць раптоўныя паломкі.

Ці можа адна шчэкавая драбнілка апрацоўваць розныя матэрыялы?

Так! Большасць шчэкавых драбілак працуюць з камянямі, бетонам і нават перапрацаванымі матэрыяламі. Аператары проста карэктуюць налады для кожнай задачы.

Час публікацыі: 18 жніўня 2025 г.